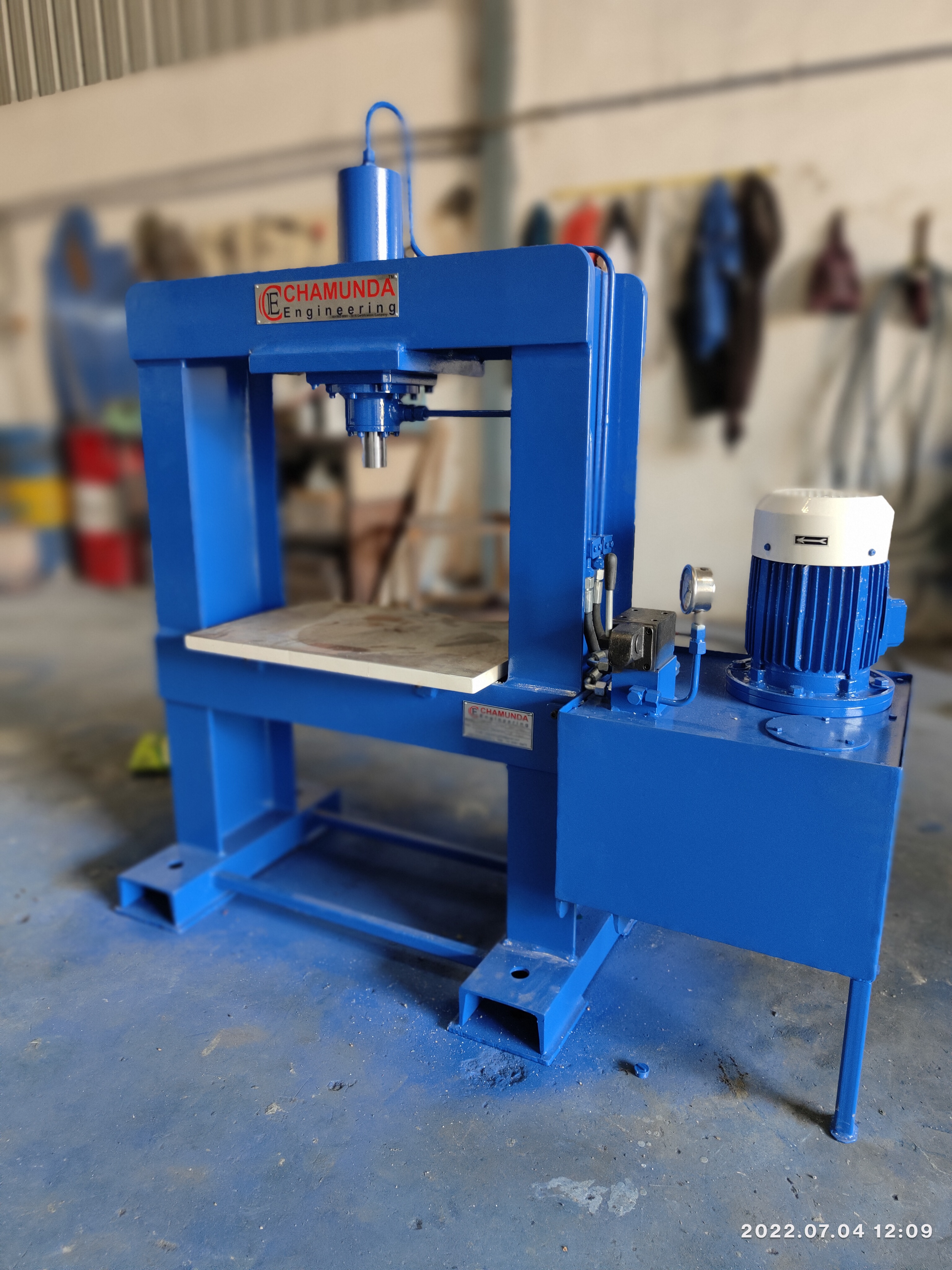

Product Features:

- Accurate clear pass between Bolster and Table Plate

- Accurate Stroking movement in Downward and Upward direction.

- Emergency stop push switch.

- T-Slot for easy clamping of Die and Punch on both Bolster and Table Plate

- Four side Hardened Rod for guide

- Adjustable Pressure Relief/Controlling Valve for HT material.

- Indication light (Tower Light) with safety alarm sound

- Safety Decals around the machine, keep operator handy.

Standard features available on most H-Type Hydraulic Presses models:

- Electric / Hydraulic operation provides smooth, consistent pressing action;

- Open sides facilitates work on long pieces;

- Easily changeable flat ram nose allows the user to adapt the press to a specific job;

- Quality, low speed Baldor motor;

- Low speed pump offers a quiet, dependable operation;

- Self-locking table design eliminates lateral movement;